That’s Delivered Podcast

Welcome to “That’s Delivered Podcast” (TDP) your ultimate destination for all things trucking and beyond! Here, we take you behind the wheel and dive deep into the world of trucking, delivering stories, insights, and experiences designed to inspire, educate, and entertain.

Our podcast isn’t just about transportation; it’s about reliability, accomplishment, and fulfillment. “That’s Delivered Podcast” reflects the sense of completion that comes with meeting promises and exceeding expectations, whether on the road or in life.

Whether you’re a seasoned trucker, a logistics enthusiast, or just curious about the backbone of our economy, this is the place for you. We’ll explore life on the road, uncover how technology is reshaping the industry, and break down the latest regulations impacting drivers and businesses alike.

So buckle up, hit the road with us, and join a community that understands the journey is just as important as the destination. From personal stories to industry insights, “That’s Delivered Podcast” brings the best of trucking straight to your ears, promising every mile together will be worth the ride!

That’s Delivered Podcast

Brent Hagen On Reliability Begins Before The Road

Reliability doesn’t start at the dock; it starts with the systems, culture, and visibility that shape every move long before a truck leaves the yard. We sit down with Brent Hagen, Chief Supply Chain Officer at Lob and former Amazon operations leader, to explore how standard work, bottoms-up ownership, and ruthless transparency turn daily chaos into dependable delivery. From running a 24/7 slice of a two-million-square-foot facility to redesigning Lob’s network without owning fixed assets, Brent shares the practices that help teams stay calm, move fast, and keep promises.

Key Takeaways 👇

🟩 Reliability starts long before the truck moves—built through culture, systems, and visibility.

🟩 Standard work + bottoms-up ownership turn daily chaos into predictable performance.

🟩 Consolidating from 30 → ~10 manufacturing partners significantly improved quality and consistency.

🟩 The most reliable carriers offer predictable lanes, strong scan visibility, and accountable exception handling.

🟩 Lob builds Amazon-like speed without fixed assets by tightly integrating manufacturers, logistics partners, and USPS injections.

🟩 Leaders evolve by shifting from “fixer” to “builder of owners” and maintaining steady rituals across all shifts.

🟩 AI pays off today in dispatch intake, exception triage, lane forecasting, trailer utilization, and cost-to-serve modeling.

🟩 Tracking data is non-negotiable—“If you don’t track it, you can’t trust it.”

🟩 Tariffs, seasonality, and resilience planning remain central to dependable supply chain operations.

🟩 Brent supports STEM through the Science Center of Iowa to help grow the next generation of logistics innovators.

Follow for more conversations at the edge of trucking, fulfillment, and technology. If this resonated, subscribe, share it with a colleague, and leave a review to help others find the show. Got a question or insight from your lane? Drop us a note—we’d love to hear it.

Interested in being a guest on the podcast? Click here to join the conversation!

Get your discount for Truck Parking Club click: here

Get your Trucking Ray merch to show that you roll with Trucking Ray and That’s Delivered Podcast! click: here

Welcome back to the Dash Delivery Podcast, where trucking meets technology, leadership, and logistics. I'm your host, Trucking Ray. And when we talk about delivery, most people think about what happens on the road, but what about everything that happens before the truck rolls? From warehouse floors to digital dashboards, reliability starts long before a freight leaves the dock. My guest today is Brent Hagen, the chief supply chain officer at Lobb, where he leads 250 million automated fulfillment network that keeps thousands of customer promises on track. Before that, he managed massive operations at Amazon to help deliver for scale for deliver ahead of Shopify's 2.2 billion acquisition. Brent has been on the front lines, helped building reliable systems. And today we're breaking down what the truck and world can learn from that. Hey Brent, thank you for being on the show today. Glad to have you here. How are you doing today?

SPEAKER_02:I'm doing great. Yeah. Thanks for having me.

SPEAKER_01:Awesome. I mean, you've had a fascinating journey from Purdue to Eton's leadership program uh to managing large-scale operations. Uh, tell us about that. How how did that go? How'd you get started with that?

SPEAKER_02:Yeah, uh, I've been I've been really fortunate throughout my career for sure, um, starting with a first-class education from Purdue. Uh I I still still go back to to campus uh usually once a semester and present to to students um about about how to kind of forge their career and and set their own their own path. Um joining Eaton's LDP uh program, I was incredibly fortunate to be a part of that. Um it still exists today, although in in a very different form than the one that I was in, um, followed by getting recruited into private equity manufacturing. Um private equity manufacturing is really where my my uh life took took a bit of a turn, uh, got married, uh, started having kids, and uh I was traveling, you know, probably 100% of the time, and uh Amazon came calling, and uh I talked to a lot of my mentors uh at the time, some of which are still my mentors today, about getting into fulfillment. And one of them had a really great advice, and he was like, you know, fulfillment's the the way of the future. He's like, you need to learn about it. He's like, they have the best technology. Uh, and so that's that's how I really uh ended up at at Amazon was taking the advice of uh of what's clearly a very wise guy. Um then moving moving into deliver, which was founded by uh ex-Amazon uh guy uh who was who was looking to uh the our thesis in this space was that that we could create Amazon-like fulfillment speeds uh without having Amazon-like uh fulfillment uh and fixed cost. You know, obviously they have uh distribution centers all over the country in order to provide that that very unique experience on it it worked, uh followed by as you called it the the Shopify acquisition. Um and then after that, uh I was on a hiatus uh hanging out with with my family when when Lob called. And that's really been this has been such a fun part of my career. Uh I knew the next role I wanted to do. Um when I was talking to our the CEO, um, I said, I just really want to solve interesting problems with with interesting people. And this is definitely an interesting one because it's such a highly fragmented space. Um, obviously very old technology uh with an industry that's been around for a really long time, right? One of the one of the largest cut uh companies in the space has been around for 150 years. So it starts to really combine uh a lot of my manufacturing background, but as well as the the technology um and operation, operational resilience that I learned throughout my career, especially at at Amazon uh and then with with Deliver. So it's it's been a really great uh combination. And uh I'm headed right towards uh my third year here. It's been a ton of fun.

SPEAKER_01:Congratulations, man. That's awesome. I mean, running 5,000 person fulfillment center at Amazon sounds intense. Well, what did you your experience teach you about efficiency and accountability? What's what did that help with?

SPEAKER_02:Yeah, well, so systems, uh a lack of systems are going to uh pop up, you know, if if you don't have um if you don't have the right standardization in place, you're gonna watch everything, everything fall apart at scale like that. You know, so uh when I started at at Amazon, I was running uh basically a third of of a building uh which had uh which was 2 million square feet, had a few thousand people inside of it, and I had about a third of the building. And I ran it 24-7. And I was the only one out of my peers and I that had 24-7. Most people have like 12 uh seven, you know, and so one person runs all night, the other person runs all day. Uh and so I obviously couldn't live there. Um, Amazon wouldn't allow it, nor would my my wife and my children certainly wouldn't like it very much. Um so it was critical for me to put processes in place uh that scaled, that allowed me to be out of the building. You know, and so the the question that I always ask teams when you're when you're thinking about that um is how are you bringing visibility to your problem? Uh how are you going to standardize how you respond to those problems? Because nobody uh can can be there all the time, even across from shift to shift. And all of them really need to kind of look the same. You know, each each shift should solve problems pretty much the same way. So, how do you standardize the way in which we look at problems, the way that we're going to attack short-term, medium-term versus long-term? And then ultimately, how do you establish uh accountability uh towards solving those problems? Like those are things that you had to become an expert at very, very quickly at Amazon uh in order to be really great. You know, the the piece that I like to talk to people about is this is operations, right? It doesn't matter if you're a fleet manager or someone running a distribution center, um, or if you're the person making the widget, you know, somewhere uh globally, operations is is pure chaos. Like every single day, something's gonna go wrong, right? Like you just you probably maybe you heard about the AWS shutdown that just happened uh overnight, right? That broke systems from Amazon to Delta Airlines, like you you name it, like that's gonna pop up. That's a pretty complicated problem. But you're gonna have people call in sick, you're gonna have a truck breakdown, you're gonna have a forklift breakdown. So what keeps us from uh absolutely falling to pieces in in those scenarios is our culture, right? Culture is the thing that's gonna make you uh be calm when the when the storm is hap, uh, is happening.

SPEAKER_01:I like that. So uh what's some of the exercises that you do to stay calm? I mean, that culture. I mean, how do you um present that to other people?

SPEAKER_02:Yeah, I I think a lot of it comes down to how you begin to structure your teams and um going back to that that standardization piece, you know, and so every day, every week, every month, every quarter, I want to look at problems the exact same way. And I want the team around me uh to talk about uh to talk about our problems, you know, and so let's use data um and enhance visibility towards that data to begin tracking where our deficiencies lie and be incredibly um uh incredibly persistent in the the pursuit of of attacking those failures, you know, and so let's not allow like one instance of a failure to ruin um the entire week or the entire month. Let's understand like how does that um come together as like a trend uh and take those trends, action them appropriately, and understand like what am I trying to fix here and how am I how do I know if that's gonna work or not? You know, and so that when teams start doing that, they uh can become very comfortable with the idea that operations is that chaos that that you and I are talking about, uh, and just kind of manage through it, you know, and so it's it's much like uh anyone that puts themselves in a situation where they have the opportunity to fail or or miss something. The first time you do it, like it's it's pretty nerve-wracking. And then it happens and you're still here, like you're still with us, like it's okay, the next day's still gonna come, you know, and so don't let some sort of opportunity to get better, don't view that as a failure. You know, and so the way I want to talk to my teams about it is every time that that happens, like as long as we're reflective about it, we're gonna learn something from that miss, you know, and so we're gonna get better the next time we do it, we're gonna enter it with a lot more comfort. Um, and that's really winning in like every sense of the uh of the term.

SPEAKER_01:Yeah, so I'm a question that comes to my mind is I've worked with some or around some individuals that like to change it every week. They they may have a process in place and they may feel like it's not being effective. So they say, well, let's change this, let's change that. And every week the whole team is changing, swinging this way, swinging that way. And what what really keeps you nailed down to the same pattern that you started out with uh initially to continue to do that week by week or uh to the next quarter and so on?

unknown:Yeah.

SPEAKER_02:So I think a lot of times when you see that, um people have leaders have like a top-down approach to problem solving, you know, and and it probably starts right there because where the where processes are most likely to fail are ones in which the the folks that are actually executing the problems uh don't have a sense of ownership around the process and of itself. So a lot of that comes down to literally like the framing of what we're trying to achieve. And so anytime that I'm goal setting, I want what we're trying to achieve, kind of our North Star key KPIs, what we want to see on a balance sheet, like whatever the case might be, that North Star should be tops down. There's there's just no doubt about it. But after that, it should, it should stop right there from the tops down and it should move bottoms up. You know, and so you should start engaging every element of your of your value chain from your frontline leaders, the hourly people on the floor, uh, your middle managers on up and think about what needs to be true in order for us to achieve these things that we're talking about. And you start laying out your your processes, you're gonna identify areas in which your systems are gonna break. Okay, great. How do we begin to fix those? How do we so we're gonna have a plan to fix those now? How are we going to monitor these things to make sure that reliability is there and that we're achieving our goals, right? And so going all the way up to how does cycle time on a machine or how does uh the rate in which we're loading our trucks or the rate in which we're turning over our trucks, uh all of our delivery speeds, how does all of that convert into what our North Star metric was? And so now you've got an action plan and processes. But what you've really done is you've engaged everyone all along the way to establish ownership in the process of what elements they control that tie back to your vision. And with that ownership, uh owners inherently feel like they need to do something in order to drive towards a result, right? Um, owners are also highly accountable to those results. So now you've also, as a leader, you've established accountability with your team. Like, hey, you own this part of the process. Uh and so that bottoms-up exercise with my team, I often say, like, hey, here's the vision, here's the things that we need to accomplish. You tell me what needs to be true. Have them really begin to design the process. Uh, now you have to help them sanity check it to make sure it's going to deliver what you what you want. Um, but then kind of get out of the way. You know, and so when you've got this ever-evolving change, I think teams often miss out on that, that process of of establishing one, a standard, uh, two, ownership and accountability, and then three, how to visualize those processes to actually understand is it working or not.

SPEAKER_01:Yeah, it's good stuff. I mean, you're well, you're always a uh hat leadership qualities. I mean, you you really uh seem to emulate everything you're saying. Um to to watch in action. I mean, I'm sure.

SPEAKER_02:Yeah, no, no, I I I appreciate it. Yeah, I appreciate it. Um, I haven't always been uh, you know, the a great a great leader. Um that was something I I absolutely had to had to learn. I've always been uh a process thinker. Like I I loved solving complex problems and being able to take a problem apart and put it back together in a more efficient way. And that was some of the first things that like I did out of school. Um but I was also kind of like a lone wolf to a certain degree. Like I also really liked doing it by myself. Uh and I so I had to figure out how to both play nice with others, but also bring people along um in that journey. Uh, and that took me a while, you know, in in my career to figure out how to be really, really good at that. Um, and the piece that I learned was how much easier it is um to have success and build on that success when you have others around you um that you're teaching, you're learning from as well, um, and you're working on this stuff together. Like it feels like an intuitive concept, you know, when I say it out loud, um, but it it wasn't for me. I had to, I had to learn that behavior.

SPEAKER_01:Wow, nice. I mean, that's that's uh it's great to see how you know humans can continue to evolve into to something that's uh they can be proud of themselves personally and also something that they can share with others. I mean, a lot of people can learn from uh from your experience. So thanks for sharing that. And uh those experiences lead to where you're at now. Um let's dig into what happens or what it looks like today. Um looks like Lobb isn't um your traditional logistics company, but it still relies on heavily on transportation partners and dependable operations. So for those in trucking who may not know, or uh those who you know uh does automated direct mail fulfillment uh network, actually, how does that work for them or how does it work for you guys?

SPEAKER_02:Yeah, good question. So Lobs started off as the um kind of the original API on the street. So it's a technology that um allows for the data transfer of marketing campaigns, transactional campaigns from, you know, whether that's a bank or Capital One or an automotive company uh into a means of manufacturing, right? And transferring that data that they need to have produced. Uh what we've transformed into is that, well, taking a step back, and we've done all of this in a third-party manufacturing manner. And historically, what we did was we sent all complexity downstream to our third-party manufacturers and we said, here's the data, go make something, uh, and please do a good job and send us the bill. Um over the last three years, we've really started to tear that apart. And we said that we really want to own the entire uh value chain without owning the fixed capital assets in the middle, right? The actual printers that are that are hat that um that are executing this. And so we've um begun leveraging our technology to integrate both with the manufacturer as well as with logistics companies, and we're handling all the procurement and stuff in the in the middle um to to execute all of our campaigns down. And so it really mimics that of a first-party vertically integrated company without us actually owning the assets in the middle. You know, and so to uh to a freight provider, we have a lot of free providers in our network that are handling our middle and final mile injection into the U USBS as well as um into our logistics partners uh kind of in the middle that might be doing middle mile sortation or co-powerization um both on FTL and and LTLs. Uh and so hopefully hopefully hope I hope, sorry, to see some of um some of your listeners' um invoices come through.

SPEAKER_01:Nice. That'd be great. I mean, so I mean Lobb's operational revenue, 50% while lowering costs. Um you've grown that, you know. Um what changes help you make that happen without sacrificing quality?

SPEAKER_02:Um one, a phenomenal team. Um, first and first and foremost. Um I was super fortunate when I came to Lobb to inherit a really good team that we've had the the opportunity to build on. Um but over the last probably 18 months, maybe two years, uh we've had this focus to uh streamline our quality processes from partner to partner. Um the first way in which to do that was that we had 30 manufacturing partners uh across the country, uh and we've dwindled those down um to about 10. That provided us um the ability to establish uh much more strategic partnerships uh across each one of our third-party manufacturers uh and align on what our vision was, what things were they already working on, where were they investing their capital as well, and what processes could each one of them control that could give us um the best tools to have uh continuity of quality across the network that was operated by by different folks? Uh and we've seen significant improvements in in quality uh over that time um while also driving more volume through our through our system. So it's something we're very excited about.

SPEAKER_01:Nice. And when you're talking about the listeners and those out there, and when you're evaluating trucking or last mile partners, what do you uh look for in a carrier uh that truly delivers consistency?

SPEAKER_02:Um versus on-time performance, um, I I think first and foremost, and their ability to provide us um very predictable freight lanes um and visibility into those freight lanes and how they're delivering, you know. And so I I don't think that there's anything more frustrating than a partner saying, like, yeah, I don't know, it's gone. Or yeah, that's shipped. And then you're like, Are you sure it's shipped? Because usually I've got this data scan that scans not here, like, you know, I I've got this pallet scan that you scan to the door or something like that, and they say, Oh, yeah, actually, you know, it never left. Like it's here at it's still here at the the DC. We accidentally put it in the in the wrong lane or something. You know, those sort of things, yes, they're they're gonna happen. Um, but they shouldn't happen all the time. You know, and uh I'll I'll give you a really good example. We we had a uh freight partner who we've been using for the last few years, and in a one-month period of time, they told us three different tractor trailers blew over and wrecked all of their pallets. And we're like, really? Like it happens, right? Like it absolutely happens, you know, no doubt. Three times in a single month, like your tractor trailers are are blown over and it's complete, you know, disaster recovery. Like, man, like I I sure would like to see pictures of those. Like that that sounds pretty interesting. Like, let me let me see that. Um, because that doesn't sound that doesn't sound truthful, you know.

SPEAKER_01:Yeah, you gotta listen to what people are saying closely because uh yeah, it could be something different out there. Yeah, I mean the human element. I mean, uh technology is changing how we work, but humans still they're still relevant. Um many fleets want to embrace the automation or AI, but if you're losing the human touch, um what balance do you think works best?

SPEAKER_02:I I look at this uh a couple of different ways. Um first and foremost, um, like there are certainly elements where AI can replace, you know, physical human touch and involved with certain things. Um when you look at it from the the um from a fleet perspective, um, there's companies like augment, for example, which are are making some of their um dispatchers and some of the intake processes more automated through leveraging AI bots and and that sort of thing. Somebody still has to manage those processes, you know, and so what I really like to focus on is what are the things that we can leverage technology for that make jobs more predictable and more efficient, you know, and so I think integrating AI into those physical human touches um allows you to do that. And that's been true even before, you know, AI, even even when we were leveraging machine learning, um, those sort of those sort of things um would always drive improvement within within your processes. And so that's how I first want to look at a technology and how do we embed it into everything? Like what are what are the areas that I can increase predictability and increase efficiency within the given workforce that I have? You know, from there you can really build um a lot of complex systems uh and that enhance your your scale while managing your overall um variable and fixed costs.

SPEAKER_01:Nice. I mean predictive data and automation are transforming uh forecasting. Uh that's it's gonna be huge for a lot of companies to be able to see further uh how to move, move to the right, move to the left. Um, what do we do? How do we assess this? Um, how close can we truly uh get to predicting supply chain disruptions before they hit the rope? What do you say?

SPEAKER_02:I think we can get pretty accurate. Um now, you know, we never know the necessarily the the next time that there's gonna be like a wild swing in tariffs. We never know the next time that there's going to be um a COVID event or something like that that just flips uh value chains upside down. Um those sort of things every few years, like those are gonna happen. Uh and it's really on us as leaders to establish agility and resilience with within our teams to be able to say, like, okay, that happened. What are we going to do and build a plan, just as you and I talked about in the earlier part of the show, right? Like, what are we trying to drive towards and and how do we do that all along the way? But in terms of um large swings, kind of planable swings that that are gonna happen, right? Like your your large Q4 congestion that's that's gonna come up related to parcel movements, right? Because of the holidays and and that sort of thing. Um, we can get really, really accurate on the impact that that's gonna have and and plan uh around that, uh leveraging machine learning, leveraging AI. Um we can even do you know future forecasts, and it says, okay, I'm getting ready to take on a large client that's a material percent, would represent a material percent of my total capacity today. Inject that into your existing data and say, like, let's model the impacts and what new freight lanes do I need to open up? Like what sort of trailer capacity is it? Um, what's my average trailer capacity going to be as a result of this? Um, as well as I think when you look at it from like a fleet owner perspective, or you know, maybe this is a 3PL owner perspective, or the way that we even look at it, as a result of adding this volume, what happens to my total cost structures and what sort of efficiency do I gain? You know, like let's leverage, let's leverage machine learning and and AI to build that out. And now I'm future for forecasting my cost basis. And so I can give this person a lower quote than what my standard quote is because I can see it's gonna materially change um my unit economics because of all of the favorabilities I'm gonna gain in trailer utilization, lane utilization, and and things like that. And so we can you can get very, very accurate with with modern day tools on on forecasting that sort of thing.

SPEAKER_01:Wow. Nice. So if you uh if you've never heard of lob or if there was uh an individual out there for hearing us for the first time, what's the simplest way that uh you would say lob would help uh a business six to be successful? Um how would you put it?

SPEAKER_02:Yeah, I think two different ways. Uh we really have two different uh two different businesses now, uh one that's very complementary to the to the other for sure. Uh we're a direct mail automation platform, and so we allow uh very easy uh execution of people's mail campaigns uh across the US, Canada, and the and the UK. Um as a complement to that business, we've launched Lob Logistics, uh, which can work with our existing customer base, the actual mail owners, uh, as well as print manufacturers uh as a means of distribution and injection into the into the USPS. Uh and so we have uh a number of partners uh across uh all the major geographies um that can reduce the the time to to in home and your your average cost uh when handling your logistics.

SPEAKER_01:Man, so for the future of fulfillment and trucking or for lob uh as automation continues to evolve, what changes do you think will most impact the trucking industry in the next few years? What would you say?

SPEAKER_02:Well, I think we have to get tariffs under control, you know, for sure. Um that's that's gonna have uh a large impact. We've we've seen that. Um I think all of us are are happy to to be operating in uh in kind of that that non-COVID environment as as well when we weren't really sure when stuff was gonna get pulled out of Savannah and Long Beach uh or Miami or or wherever wherever else. Um but the um yeah, that's that's really kind of it.

SPEAKER_01:Yeah. I mean that's uh it's a huge thing to try to predict is I mean, what's gonna happen from another country to what's gonna happen here and how they're gonna interact with each other. I mean, tariffs is uh it is very unpredictable. So yeah, you're right about that.

SPEAKER_00:No doubt.

SPEAKER_01:Uh it looks like you also serve on the board of Science Center of Iowa. Did I get that correct? Yeah, that's right. All right. So how does uh the education curiosity play in development of next generation um for logistic leaders?

SPEAKER_02:Well, it's uh it's really important to me to serve on boards like that. Um the the Science Center of Iowa in particular, uh, we even have like a preschool and early education uh to get kids involved in in STEM uh and and understanding uh technology and science and uh the impact that that that can have. Um so it's it's a pretty unique early education, uh, but as well as it it begins to bring this family uh together, both of entrepreneurs and local businesses, and uh that really kind of some of which are leaders in other parts of the state and country, um, that allows for idea sharing uh that can be wildly beneficial. You know, you start establishing better partnerships, uh, but as well as that sense of community that comes from being a part of that sort of like philanthropic uh uh effort. Um, I want to uh help educate whoever I can uh on the on the benefits of of science and technology, you know, and so especially coming from my part of the world and in operations, um, things don't have to be kind of this this fixed mindset that they have been in in operations and supply chain for for a really long time, right? How do we leverage technology and engineering to to uh build better solutions? Um the science center of Iowa like allows me to to do those things.

SPEAKER_01:Wow, nice. And for anyone, um, I mean, that's uh that's a huge thing for anyone that's listening. Um, I mean, we definitely want to help the future of young ones to be successful, so I really appreciate you doing that. So also from drivers to dispatchers, what's one step that you can take um or that people can take um maybe just uh this week to make their operation more reliable and future ready?

SPEAKER_02:Yeah, good question. Um I think I can keep it really simple. Like if you don't track it, you can't trust it. You know, and so what what are you doing to provide visibility to your team on all the sources of of error that can pop up within your within your operation? Um if you're not tracking those opportunities to miss, eventually you're going to miss, right? Like those things are going to happen. So if you don't track it, you can't trust it.

SPEAKER_01:I like that. And real nice and simple and something that you can put forth the effort uh to improve each day. Uh even if you're changing it just by 1%, you're going in the right direction versus uh just letting it happen, right? So great. Um, and you're a true leader. Uh you've definitely grown uh into the person that people need. We need someone more people like you in the industry. So I'm really glad that you came on the show to share your experience and also talk about uh the things you're doing over there at Lobb, the things you have done and you continue to do. Um it's much appreciated. So thank you so much, Brent.

SPEAKER_02:Yeah, thank you. I appreciate you having me.

SPEAKER_01:Yeah. So um thanks for joining Das Deliver Podcast. It's clear behind every delivery, every model. And every one-time promise, there's strategy, leadership, and teamwork that keeps it all together. So thank you for providing that. And then so before we go, uh to learn more about lob's approach and fulfillment, um, uh, where's the best place for people to reach out? Is it lob.com or where else are we going to go?

SPEAKER_02:Lob.com. Yeah, they can also find me uh on LinkedIn under Brent Hagen. Um happy to to connect and and talk about what's going on in in my world and theirs.

SPEAKER_01:Nice. Any else, anything else you'd like to share with uh listeners out there or some of the truckers before we go, I like to always see if you know if you've just wanted to put a shout out or a thank you for anybody out there. Just uh uh we want to make sure that they hear it too. So um anything No, no, that's that that's it.

SPEAKER_02:I I appreciate you having me. Um the only shout out is is to my team for for everything that they uh they do for us and the business and our our customers. Uh and for your your listeners, hopefully some of them are uh vendors of ours. Thank you for for what you do. Uh it's not a it's not an easy job for sure.

SPEAKER_01:Awesome, awesome. Thank you so much. And uh and if anybody likes what you hear or like what you see, please be sure to subscribe and also continue to listen. If you have any questions or comments, please leave those for us. We'd like um like hearing from you, like uh answering your questions, and um please reach out at that'sdelivered.com or anywhere that you get your podcasts. So that's all for today. And um, we're trucking meets innovation, and that's delivered.

Podcasts we love

Check out these other fine podcasts recommended by us, not an algorithm.

Channel 19 Experience Trucker Podcast

Channel 19 Experience

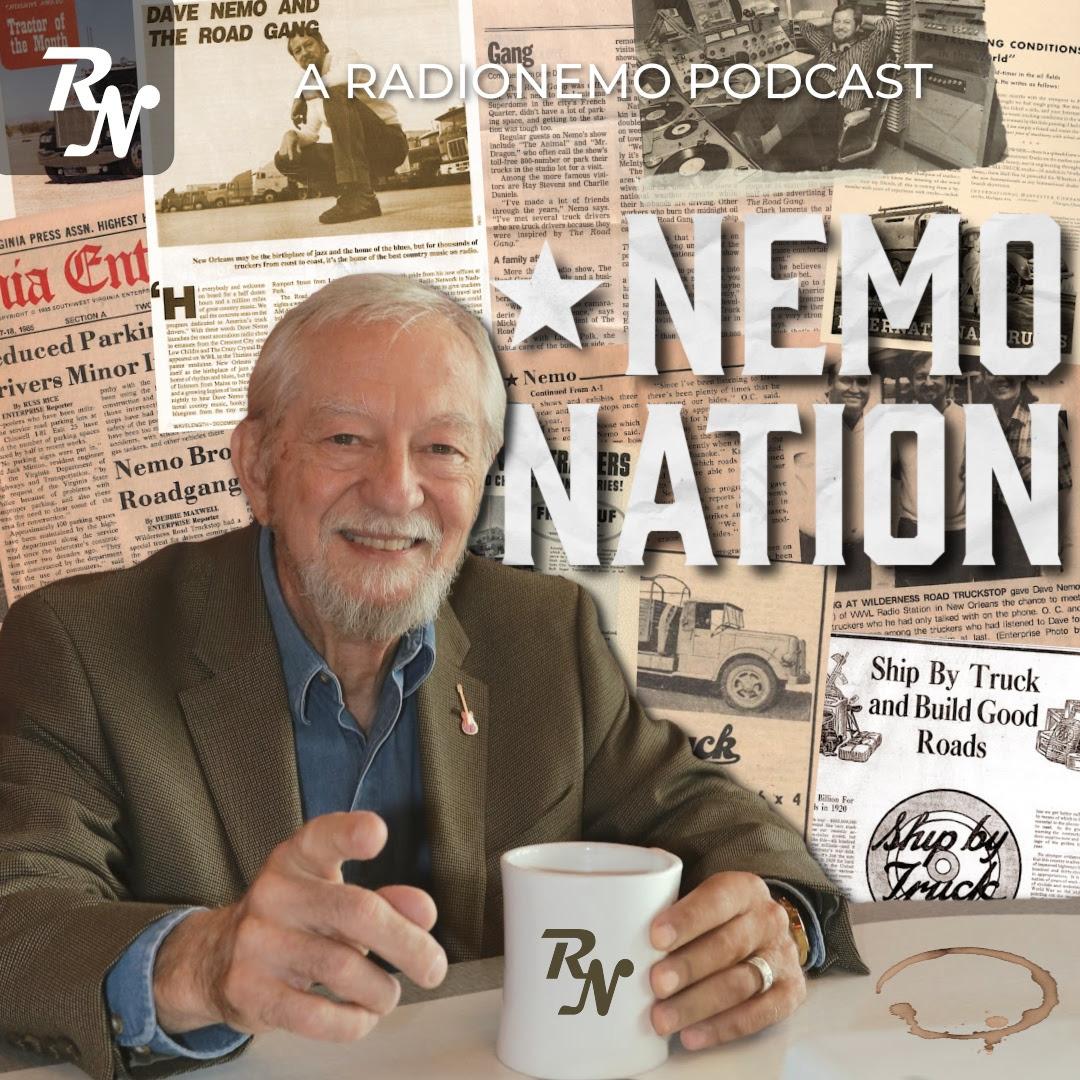

Nemo Nation

Nemo Nation